Thermal Interface Materials

Better cooling for better performance.

The performance of electronic devices is constantly improving, but they consume more power and generate greater heat. If heat can not escape efficiently, the performance of the device suffers. That's why thermal interface materials are becoming such an important technology in the electronics industry. Silicone-based thermal interface materials are compound materials which contain a high ratio of thermally conductive fillers. They exhibit outstanding thermal conductivity because they fit snugly in the gap between the heat-generating unit and the heatsink.

Shin-Etsu Silicone has the solution for heat dissipation. Our diverse lineup of products is designed for a range of applications and performance requirements.

Application examples

- Heat dissipation for power transistors and power modules

- Heat dissipation for electronics devices

(notebook PCs, LED lighting, hybrid cars, electric cars, and others)

Product lineup

Oil Compounds

Thermally conductive oil compounds are grease-like products containing silicone fluids as a base oil, and thermally conductive fillers such as alumina powder. Silicone oil compounds show excellent stability against thermal oxidation, in addition to excellent electrical properties over a wide temperature range.

Main Features

- Excellent thermal conductivity

- Grease-like products can be screen printed

- These products show the following characteristics due to their excellent heat and cold resistance:

- High dropping point

- Less oil separation and lower volatile matter

- Good stability against thermal oxidation

- Good stability against consistency changes

- No solidification at temperatures under 0°C

Primary Applications

Schematic diagram

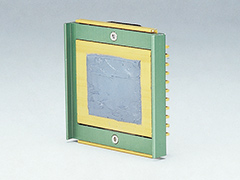

- Good performance is obtained when these materials are used for thermal conductivity of semiconductor devices such as power transistors, ICs, and CPUs

- For thermal conductivity of resin-encapsulated power transistors

- These materials are best suited for potting between heatsinks and such components as transistors, rectifiers, and thyristors

- For sealing the measuring parts of thermistors, thermocouples, etc.

- For potting of heat-generating components in devices such as heaters, and heat dissipaters

General Properties

| Grade | G-751 | X-23- 7762 |

X-23- 7783D |

X-23- 7868 -2D |

X-23- 7921-5 |

G-775 | G-776 | G-777 | G-779 |

|---|---|---|---|---|---|---|---|---|---|

Color and Consistency |

Gray | Gray | Gray | Gray | Gray | White | White | White | White |

Viscosity at 25°C Pa·s |

420 | 180 | 200 | 100 | 360 | 500 | 60 | 140 | 160 |

Specific Gravity at 25°C |

2.51 | 2.55 | 2.55 | 2.5 | 2.8 | 3.4 | 2.9 | 3.2 | 3.2 |

Thermal |

4.5 | 4.0 (6.0*2) |

3.5 (5.5*2) |

3.6 (6.2*2) |

6.0 | 3.6 | 1.3*2 | 3.3 | 3.0 |

Thermal |

17 (62µm) |

15 (73µm) |

8.0 (38µm) |

7.0 (25µm) |

5.8 (25µm) |

25 (75µm) |

7.4 (7.8µm) |

21 (56µm) |

10.6 (25µm) |

Breakdown |

Below measurable limit | 2.5 | 2.9 | 3.2 | 3.2 | ||||

Volatile Content |

0.10 | 2.58 | 2.43 | 2.70 | 0.44 | 0.26 | 3.10 | 0.1 | 0.18 |

Usable |

-50 to +120 |

-50 to +120 |

-50 to +120 |

-50 to +120 |

-50 to +120 |

-40 to +150 |

-40 to +200 |

-40 to +200 |

-40 to +200 |

*1 Measured with hot disc method. *2 After solvent evaporation.

(Not specified values)High-hardness Thermal Interface Silicone Rubber

The high-hardness TC Series products have excellent insulation. These products are composite products of silicone rubber combined with fillers to enhance heat dissipation. These materials are pliable and adhesive, and are best suited for use as a sealant to heat-generating components and heatsinks. They exhibit superior thermal conductivity.

Main Features

- These products have fine electrical properties (electric non-conductivity, etc.)

- There is a reinforcement type with the Fiberglass or Polyimide film.

- All products are UL-certified for flame-retardancy.

- Can be used in a wide temperature (-40 °C to +180 °C).

Primary Applications

- For thermal conductivity and electrical insulation for power transistors and power modules

- For thermal conductivity, electrical insulation and vibration damping of semiconductor devices such as CPUs and electrical components

- TC series act as heat dissipaters, electrical insulators and thermal conductivity for thermal fuses and temperature sensors

Structure

Schematic diagram

General Properties

| Type | High-hardness Thermal Interface Silicone Rubber | ||||||

|---|---|---|---|---|---|---|---|

| Sheet type | |||||||

Paratemer Series |

TC-TA-1 Series |

TC-TAG-2 Series |

TC-TAP-2 Series |

TC-TAG-3 Series |

TC-TAG-8 Series |

TC-BG Series |

|

Color |

Deep brown | Purple | Light purple | Dark gray | Light gray | White | |

Reinforcement Layer |

None | Fiberglass | Polyimide film | Fiberglass | Fiberglass | Fiberglass | |

Size mm |

300x1,000 | 300x1,000 Roll |

320x1,000 Roll |

300x1,000 Roll |

420x500 | 210x270 | |

Thickness mm |

0.20, 0.30 0.45 |

0.20, 0.30 0.45, 0.80 |

0.11 | 0.20, 0.30 0.45 |

0.20, 0.30 0.45 |

0.20, 0.30 0.45 |

|

| Properties of Representive Products | TC-30TA-1 (Thickness: 0.30mm) |

TC- 30TAG-2 (Thickness: 0.30mm) |

TC- 11TAP-2 (Thickness: 0.11mm) |

TC- 30TAG-3 (Thickness: 0.30mm) |

TC- 30TAG-8 (Thickness: 0.30mm) |

TC-30BG (Thickness: 0.30mm) |

|

Thermal Conductivity, |

ISO 22007-2*1 |

1.0 | 1.8 | 1.8 | 3.4 | 8.0 | 7.3 |

Thermal Conductivity |

ISO 22007-2*1 |

1.1 | 1.4 | 0.9 | 2.1 | 4.7 | 4.0 |

Thermal Resistance |

ASTM D5470 | 3.8 | 2.5 | 2.0 | 1.7 | 1.0 | 1.9 |

Density at 23°C g/cm3 |

JIS K 6249 | 1.70 | 1.86 | 1.65 | 2.84 | 1.56 | 1.66 |

Hardness Durometer A |

JIS K 6249 | 70 | 91 | 87 | 90 | 83 | 91 |

Dielectric Breakdown |

JIS K 6249 | 15 | 10 | 8 | 9 | 8 | 15 |

Dielectric Strength Air kV |

JIS C 2110 | 15 | 7 | 6 | 7 | 7 | 13 |

Volume Resistivity TΩ・m |

JIS K 6249 | 5.4 | 3.5 | 14.0 | 0.9 | 5.4 | 68.0 |

Flame retardance UL94 |

- | V-0 (UL file No. E48923) | |||||

Low-Molecular-weight |

Shin-Etsu method*2 |

40 | 30 | < 10 | < 10 | 20 | < 0 |

*1 Hot disk method

*2 Aceton extraction method

* We provide not only sheet, but also Cap or Tube shapes. So if you need them, please contact our sales department.

Thermal Interface Silicone Soft Pads / Ultra Soft Pads

Thermal interface silicone soft pads / ultra soft pads are made of silicone rubber combined with thermally conductive fillers. The line-up are single layer type and composite type. They are soft with good adhesion, so they bonding tightly to the heat-generating unit and the heatsink, providing more efficient cooling.

Main Features

Application of pad

- These products are capable of close conformity to irregular or complex surfaces.

- They are easy to apply and remove, and can be used for temporary attachment.

- All products are UL-certified for flame-retardancy.

- Excellent cost performance and high thermal conductivity.

- Can be used in a wide temperature (-40°C to +180°C).

Primary Applications

- Heat dissipation for MPUs of computers, etc.

- Heat dissipation for surface packaging microchips which generate high heat.

Structure

General Properties

| Type | Thermal Interface Silicone Soft Pads | ||||

|---|---|---|---|---|---|

Paratemer Series |

TC-HSV-1.4 Series |

TC-TXS Series |

TC-TXS2 Series |

TC-SP-1.7 Series |

|

Color |

Gray | Gray | Gray | Light blue, Gray | |

Size mm |

300x400 | 300x400 | 300x400 | 300x400 | |

Thickness*1 mm |

0.5, 1.0, 1.5 2.0, 2.5, 3.0 |

0.5, 1.0, 1.5 2.0, 2.5, 3.0 4.0, 5.0 |

0.5, 1.0, 1.5 2.0, 2.5, 3.0 4.0, 5.0 |

0.5, 1.0, 1.5 2.0, 2.5, 3.0 4.0, 5.0 |

|

| Properties of Representive Products | TC-HSV-1.4 (Thickness: 1.0mm) |

TC-TXS (Thickness: 1.0mm) |

TC-TXS2 (Thickness: 1.0mm) |

TC-SP-1.7 (Thickness: 1.0mm) |

|

Thermal Conductivity, |

ISO 22007-2*3 | 1.2 | 3.3 | 3.3 | 1.5 |

Thermal Resistance |

ASTM D5470 | 6.9 | 2.7 | 2.2 | 8.2 |

Density at 23°C g/cm3 |

JIS K 6249 | 2.5 | 3.1 | 3.1 | 2.3 |

Hardness Asker C*2 |

JIS K 6249 | 25 | 45 | 20 | 2 |

Dielectric Breakdown |

JIS K 6249 | 23 | 20 | 21 | 20 |

Dielectric Strength |

JIS C 2110 | 18 | 18 | 17 | 16 |

Flame retardance UL94 |

- | V-0 (UL file No. E48923) | |||

Low-Molecular-weight |

Shin-Etsu method*4 |

260 | 240 | 600 | 240 |

(Not specified values)

*1 About the lineup of other thicknesses please contact our sales department.

*2 Thickness (Asker C): Measured using 2 overlapping thermal interface silicone soft pads (Thickness: 6 mm).

*3 Hot disk method *4 Aceton extraction method

| Type | Thermal Interface Silicone Ultra Soft Pads | |||||

|---|---|---|---|---|---|---|

Paratemer Series |

TC-CAS-10 Series |

TC-CAB-10 Series |

TC-CAD-10 Series |

TC-CAT-20 Series |

TC-CAF-40 Series |

|

Color |

Dark gray | Pink | Light reddish-purple | Gray | Light purple | |

Size mm |

300x400 | 300x400 | 300x400 | 300x400 | 300x400 | |

Thickness*1 mm |

0.5, 1.0, 1.5 2.0, 2.5, 3.0 4.0, 5.0, 6.0 7.0, 8.0, 9.0 10.0 |

0.5, 1.0 1.5, 2.0 2.5, 3.0 4.0, 5.0 |

0.5, 1.0 1.5, 2.0 2.5, 3.0 4.0, 5.0 |

0.5, 1.0 1.5, 2.0 2.5, 3.0 4.0, 5.0 |

0.5, 1.0 1.5, 2.0 2.5, 3.0 4.0, 5.0 |

|

| Properties of Representive Products | TC-CAS-10 (Thickness: 1.0mm) |

TC-CAB-10 (Thickness: 1.0mm) |

TC-CAD-10 (Thickness: 1.0mm) |

TC-CAT-20 (Thickness: 1.0mm) |

TC-CAF-40 (Thickness: 1.0mm) |

|

Thermal Conductivity, |

ISO 22007-2*3 | 1.8 | 2.3 | 3.2 | 4.5 | 5.2 |

Thermal Resistance |

ASTM D5470 | 3.3 | 2.4 | 2.2 | 1.6 | 1.5 |

Density at 23°C g/cm3 |

JIS K 6249 | 1.9 | 2.2 | 3.0 | 3.2 | 3.3 |

Hardness Asker C*2 |

JIS K 6249 | 10 | 10 | 10 | 20 | 40 |

Dielectric Breakdown |

JIS K 6249 | 22 | 22 | 15 | 15 | 16 |

Dielectric Strength |

JIS C 2110 | 10 | 11 | 11 | 11 | 11 |

Flame retardance UL94 |

- | V-0 (UL file No. E48923) | ||||

Low-Molecular-weight |

Shin-Etsu method*4 |

240 | 220 | 180 | 260 | 90 |

(Not specified values)

*1 About the lineup of other thicknesses please contact our sales department.

*2 Thickness (Asker C): Measured using 2 overlapping thermal interface silicone ultla soft pads (Thickness: 6 mm).

*3 Hot disk method *4 Aceton extraction method

Thermal Interface Phase Change Materials

Thermal Interface Phase Change Materials are thermally conductive sheets which undergo phase-change and soften when exposed to heat. The following performance parameters have been improved.

Main Features

Application of PC heatsinks

- After phase-change, the PCM conforms tightly to uneven surfaces.

- Silicone based PCM are highly resistant to pump-out.

- Easy transfer for high process efficiency.

Primary Applications

- Heat transfer medium for use with heat-generating devices such as PCs, DVD drives, power supply units, etc.

- Heat dissipation for heat-generating electronic components.

Improving close contact reduces thermal resistance.

General Properties

| Grade | PCS-CR-10 | PCS-PL-30 | |

|---|---|---|---|

Color |

- | White | White |

Initial Thickness µm |

- | 200 | 120 |

Bond Line Thickness*1 µm |

Micro gauge | 10 | 30 |

Reinforcement Layer |

- | None | Polyimide film |

Density at 23°C g/cm3 |

JIS K 6249 | 2.9 | 2.7 |

Dielectric Breakdown |

JIS K 6249 | - | 5.5*3 |

Softening Point °C |

Shin-Etsu method | Approx.50 | Approx.50 |

Thermal Conductivity W/m·K |

ASTM E1461*2 | 2.0 | 1.7*4 |

Thermal Resistance*1 cm2·K/W |

ASTM E1461*2 | 0.08 | 0.73 |

Size mm |

- | 300x400, Roll | 320x400, Roll |

Flame Retardance UL94 |

- | V-0 equivalent | V-0 equivalent |

*1 After 1 hour compression, 50 psi / 100°C

*2 Laser flash method.

*3 Measured by initial thickness.

*4 Thermal conductivity of PCM.

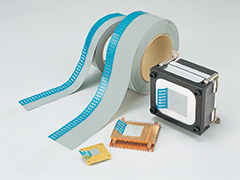

Double Sided Thermal Interface Silicone Tapes

Thermal interface tape: Single layer, double-sided adhesive. New lineup will include 100 µm and 200 µm thicknesses.

Main Features

- Strong and stable adhesive strength without screws.

- Thermal resistance is stable across a wide temperature range.

- Can be applied to wide areas using automated equipment.

Primary Applications

- Heat dissipation for power transistors

- Heat dissipation for substrates

Reliability test data

General Properties

| Grade | TC-10SAS | TC-20SAS | ||

|---|---|---|---|---|

Color |

- | White | White | |

Size mm |

- | 300x400 | 300x400 | |

Matrix |

- | Silicone | Silicone | |

Thickness*1 µm |

- | 100 | 200 | |

Dielectric Breakdown Voltage Air kV |

JIS K 6249 | 3 | 6 | |

Thermal Conductivity W/m·K |

ASTM E1461*3 | 1.0 | 1.0 | |

Thermal Resistance cm2·K/W |

ASTM E1461*3 | 2.0 | 2.9 | |

Peeling Strength*2 |

Aluminum |

- | 6.0 | 6.4 |

SUS |

- | 7.0 | 7.6 | |

Glass epoxy |

- | 7.6 | 8.1 | |

Flammability UL94 |

- | V-0(UL file No. E48923) | ||

(Not specified values)

*1 About the lineup of other thicknesses please contact our sales department.

*2 After sticking a tape on a test plate, then pressed down using a 2 kg roller.

After 10 minutes, the tape was then peeled off in the 180-degree direction and measurements taken.

(Temp.: 23°C, peeling speed: 300 mm / min)

*3 Laser flash method

Condensation-cure Type Liquid Silicone Rubber

Shin-Etsu condensation curing silicone rubbers are one component type adhesives compounded with a special filler to enhance thermal conductivity. These materials are in liquid or paste form before curing. When exposed to the air, they start to cure while generating a small amount of cure by-product.

Main Features

- Excellent thermal conductivity a Easy to handle.

- Excellent adhesion a Superior electrical properties.

- These materials exhibit outstanding heat and cold resistance, and show stable properties in a wide temperature range from -40°C to 180°C.

Primary Applications

Application of liquid rubber

- For sealing and thermal conductivity of electrical and electronic components

- For sealing of thermocouples

- Heat-dissipation for optical pickup diodes aFor sealing of heat exchangers

- Better performance can be obtained when these materials are used as a heat bonding material for the joints

General Properties

| Type | One-component adhesive type, Condensaton cure | ||

|---|---|---|---|

| Grade | KE-4961-W | KE-4962-W | G-1000 |

Cure Type (by-product gas) |

Condensation (Alcohol) |

Condensation (Alcohol) |

Condensation (Acetone) |

Appearance |

White | White | White |

Viscosity at 23°C Pa·s |

- | - | 80 |

Density at 23°C g/cm3 |

2.34 | 2.65 | 3.04 |

Hardness Durometer A |

80 | 88 | 40 (Asker C) |

Tensile Strength MPa |

3.9 | 4.4 | - |

Elongation at break % |

60 | 30 | - |

Volume Resistivity TΩ·m |

1.0 | 1.0 | - |

Thermal Conductivity* W/m·K |

1.6 | 2.4 | 2.4 |

Dielectric Constant 50Hz |

4.3 | 4.4 | - |

Dielectric Dissipation Factor 50Hz |

1×10-1 | - | - |

Dielectric |

24 | 25 | 14 |

Tack Free Time min |

1 | 2 | 3 |

Lap Shear Strength (Al/Al) MPa |

0.7 | 0.8 | - |

Flammability UL94 |

V-0 | V-0 equivalent | - |

Low-Molecular-weight |

< 300 | < 300 | < 100 |

Curing conditions: 23°C±2°C, 50±5% RH × 7days

* Measured with hot-wire method.

Addition-cure Type Liquid Silicone Rubber

Shin-Etsu silicone rubber products, compounded with special filler to enhance the properties of thermal conductivity, are heat curable addition cure type and can thus be uniformly cured in a short period of time regardless of the thickness of the rubber.

Main Features

- Excellent thermal conductivity a Excellent electrical properties.

- Superior heat and cold resistance a Deep section curing is possible.

- Excellent resistance to chemicals and medicine a Superior flame retardant properties.

Primary Applications

Application of liquid rubber

- As sealant for heatsinks and pipes

- As sealing materials for thermal conductive circuits

- As protection and thermally conductive potting materials for electrical and electronic components

- As molding materials for thermally conductive parts and components

General Properties

| Type | One-component adhesive type, Addition cure |

Two-component adhesive type, Addition cure |

||||

|---|---|---|---|---|---|---|

| Grade | KE-1867 | KE-1869 | KE-1891 | KE-1897-A/B | KR-1898-A/B | |

Appearance |

Gray | Light gray | Light gray | A: Gray / B: White |

A: Gray / B: White |

|

Viscosity at 23°C Pa·s |

70 | 30 | Paste | A: 17 / B: 7 | A : 22 / B : 14 | |

Density at 23°C g/cm3 |

2.92 | 2.52 | 3.06 | 2.61 | 2.86 | |

Hardness |

Durometer A |

75 | - | 96 | 20 | 22 |

Penetration |

- | 30 | - | - | - | |

Tensile Strength MPa |

2.1 | NA | 5.3 | 0.4 | 0.4 | |

Elongation at break % |

60 | NA | 10 | 100 | 60 | |

Volume Resistivity TΩ·m |

1.2 | 3.0 | 3.4 | 0.2 | 6.0 | |

Thermal Conductivity* W/m·K |

2.2 | 1.1 | 4.0 | 1.6 | 2.2 | |

Dielectric Constant 50Hz |

6.7 | 5.3 | - | 6.0 | - | |

Dielectric Dissipation Factor 50Hz |

4.5×10-3 | 2×10-3 | - | 0.6×10-2 | - | |

Dielectric |

23 | 24 | 25 | 25 | 19 | |

Standard Curing Condition |

120°C×1h | 120°C×1h | 120°C×1h | 120°C×1h | 120°C×1h | |

Lap Shear Strength |

0.8 | - | 0.8 | 0.3 | 0.3 | |

Flammability UL94 |

V-0 | - | V-0 | V-0 | V-0 | |

Blend Ratio |

NA | NA | NA | 100 : 100 | 100 : 100 | |

Low-Molecular-weight |

< 300 | - | < 300 | < 500 | < 500 | |

* Measured with hot-wire method.

(Not specified values)