Shin-Etsu Silicone is a firm comprising three integrated dimensions: sales, research and manufacturing. Our extensive product lineup allows us to meet diverse customer needs.

Shin-Etsu can provide full customer support, based on a partnership relationship with the customer.

At Shin-Etsu, a "market in" philosophy underlies our approach to business. The silicones business encompasses an incredible array of applications in diverse industries. A marketing strategy centered on close, direct ties with customers is essential. Shin-Etsu Chemical is keenly attuned to technological and consumer trends and customer needs. We take a proactive approach to sales; we work with customers to determine their specific needs and provide tailored solutions, and provide support toward the development of end products with high added value.

Harnessing the limitless potential of silicones to add new value to your business.

Whether you're just starting on development of a new product, or have hit a wall along the way, Shin-Etsu Silicone is here for you. With silicones, the possibilities are virtually endless, and the key to unlocking them lies in molecular design. Our engineers make use of advanced molecular manipulation technology, polymerization technology, crosslinking technology and compounding technology to create materials with more sophisticated functionality. A vital element of our R&D strategy is customer input. Shin-Etsu Chemical will work with you to harness the full potential of silicones and help put it to work for your business.

Silicone-Electronics Materials Research Center

(located in Annaka, Gunma Prefecture)

This is the epicenter of our silicon chemistry research. Here we conduct wide-ranging R&D on everything from basic technologies to applications. Our R&D program focuses on silicones and organic electronic materials, and the associated synthesis technology, composites technology, formulation, fabrication and manufacturing processes.

![]() Construction of a new research building at Silicone-Electronics Material Research Center

Construction of a new research building at Silicone-Electronics Material Research Center

Specialty Chemicals Research Center

(located in Joetsu, Niigata Prefecture)

Leveraging our proprietary organic synthesis technologies, we conduct R&D on cellulose derivatives, aroma chemicals, synthetic pheromones and special silanes.

Cosmetic Application Laboratory

(Japan and Overseas Bases)

This is a base for developing cosmetic silicone formulations and providing technical services.

We have established bases in Japan and overseas and conduct activities closely tailored to the needs of each market and customer.

Shin-Etsu Molding Technical Laboratory

(Higashimatsuyama City, Saitama Prefecture)

This is a base for research into silicone rubber molding technology and mass production technology. We conduct demonstration experiments on the moldability and mass productivity of silicone rubber mainly by injection molding, and evaluate molded products to develop materials with excellent moldability.

An integrated production system ensures a consistent supply of high quality products.

Shin-Etsu Chemical produces its own supply of metallurgical silicon, the primary raw material of silicones. Integrated production from raw materials to end-product enables us to deliver a consistent supply of high quality products. We have established production systems that are both safe and eco-friendly, utilizing production technologies cultivated in-house over more than 60 years in the business. Shin-Etsu produces a diverse line of products at high efficiency and speed, thanks to a strategy of focused production and carefully designed computerized production control systems.

Naoetsu Plant

(Niigata Prefecture)

Takefu Plant

(Fukui Prefecture)

Shin-Etsu Chemical's adherence to quality control rooted in receipt of Deming Prize.

Shin-Etsu Chemical began tackling "QC" at the relatively early date of 1950, and went to work to establish quality control methods. Then, after a mere three years, it received the Deming Prize in 1953 for its efforts.

Since 1987, when the International Standards Organization (ISO) set forth the ISO 9000 Series of international standards for evaluation of management systems, the Shin-Etsu Group has received ISO 9000 certification at almost all of its production facilities. In addition, Shin-Etsu is regularly executing quality audits of each facility's products. We are meeting the needs of the times through unflagging pursuit of quality control.

Shin-Etsu Chemical is committed to protecting the environment and reducing our environmental impact, as part of a larger effort to build a more sustainable society.

The following table lists the offices and plants that have received ISO certification for their implementation of Quality Management Systems (ISO 9001), Environmental Management Systems (ISO 14001) and Energy Management Systems (ISO 50001).

| Region | Office | ISO 9001 | ISO 14001 | ISO 50001 |

|---|---|---|---|---|

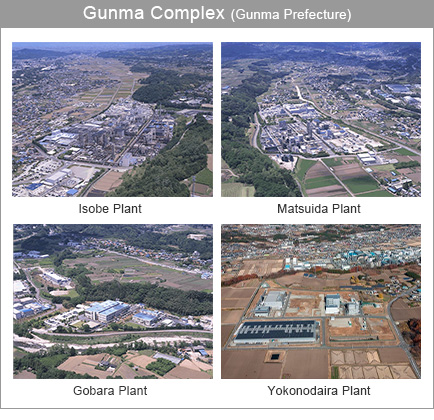

| Japan | Gunma Complex Isobe Plant / Matsuida Plant / Gobara Plant |

ISO 9001:2015 | ISO 14001:2015 | - |

| Naoetsu Plant | ISO 9001:2015 | ISO 14001:2015 | - | |

| Takefu Plant | ISO 9001:2015 | ISO 14001:2015 | - | |

| The U.S. and Europe | Shin-Etsu Silicones of America, Inc. (U.S.A.) Akron Plant |

ISO 9001:2015 | - | - |

| Shin-Etsu Silicones of America, Inc. (U.S.A.) Freeport Plant |

ISO 9001:2015 | - | - | |

| Shin-Etsu Silicones Europe B.V. (The Netherlands) |

ISO 9001:2015 | - | - | |

| Asia | Shin-Etsu Silicone Korea Co., Ltd. | ISO 9001:2015 | ISO 14001:2015 | - |

| Shin-Etsu Silicone Taiwan Co., Ltd. | ISO 9001:2015 | ISO 14001:2015 | - | |

| Shin-Etsu Silicones (Thailand) Ltd. | ISO 9001:2015 | ISO 14001:2015 | ISO 50001:2018 | |

| Asia Silicones Monomer Ltd. | ISO 9001:2015 | ISO 14001:2015 | - | |

| Zhejiang Shin-Etsu High-Tech Chemical Co., Ltd. | ISO 9001:2015 | - | - | |

| Shin-Etsu Silicone (Nantong) Co., Ltd. | ISO 9001:2015 | ISO 14001:2015 | - |

Shin-Etsu Chemical is also committed to safety. We conduct HAZOP* and other safety-related studies when planning new facilities and equipment. Meanwhile, our Safety Inspection Committee studies ways to improve safety and reduce our environmental impact. We also conduct HAZOP studies on existing facilities aimed at making improvements to work procedures and equipment, and have a program of regular safety inspections carried out by key personnel at our plants.

* A HAZOP, or "Hazard and Operability Study", is used to assess safety in a chemical plant. Used extensively worldwide, HAZOPs are systematic studies that help ensure that problems do not go uncorrected.