- HOME

- Pick Up Products

Pick Up Products

Here are some pickup products using Shin-Etsu Silicone.

-

Low Density LIMS

Low density allows for lightweight molded products. Can be used without post cure, reducing CO2 emissions. Injection molding allows for automation of molding.

-

High Heat Resistant Silicone Rubber

It is resistant to deterioration even at 300℃ and has excellent high-temperature properties. It is available in a brown and an ivory that can be colored. Hardness range from 40 to 80 (Durometer A).

-

Vibration Control Silicone Rubber (Low Dynamic Magnification)

Excellent vibration-proofing properties over a wide temperature range. Low dynamic magnification type with low frequency dependence of elastic modulus E'. Hardness range from 40 to 70 (Durometer A)

-

No Post Cure LIMS (High Tear Strength)

Low molecular weight siloxane is significantly reduced and post cure is not required, reducing CO2 emissions. It has high tear strength and excellent mechanical strength. Suitable for healthcare applications.Compliant with food-related standards. Injection molding allows for automation of molding.

-

Self-adhesive LIMS (General Purpose)

Primer is not required and it self-adheres to resin and metal without adhesive. It can adhere to a wider variety of resins and metals than our conventional products. Injection molding allows for automation of molding. Hardness range from 40 to 60 (Durometer A).

-

Self-Adhesive LIMS (Conforms to Food Standards)

Primer is not required, and it self-adheres to polycarbonate, polybutylene terephthalate, etc. without the need for adhesives. Compliant with food-related standards (FDA Compliant). Injection molding allows for automation of molding. Hardness range from 30 to 60 (Durometer A).

-

No Post Cure LIMS (Oil Bleeding)

Low molecular weight siloxane is significantly reduced and post cure is not required, reducing CO2 emissions. As it is an oil-bleed type, it is ideal for waterproof sealing of wire harnesses, etc. Injection molding allows for automation of molding.

-

Vibration Control HCR | Vibration Control Silicone Rubber (High Decrement)

Excellent vibration-proofing properties over a wide temperature range. High loss factor, high decrement type. Hardness range from 30 to 70 (Durometer A)

-

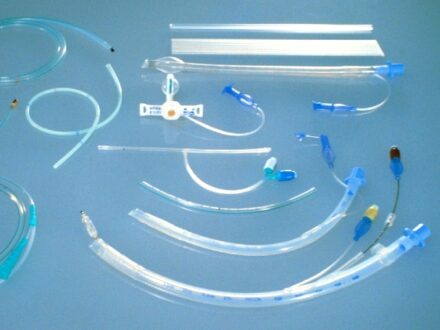

High Strength Silicone Rubber (Conforms to Food Standards)

Excellent rubber strength. Suitable for healthcare applications. Compliant with food-related standards. Excellent moldability. Hardness range from 40 to 70 (Durometer A).

-

High Cold and Radiation Resistant Silicone Rubber

Resists embrittlement even at -100℃ and has excellent low-temperature properties. It has low compression set and excellent sealing properties, especially at low temperatures. Excellent resistance to radiation such as gamma rays. Hardness is 30 and 60 (Durometer A)