X-34-4347-A/B, X-34-4352-A/B

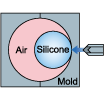

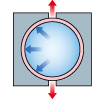

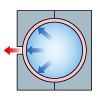

Low-density LIMS (liquid silicone rubber injection molding system) is suitable for reducing the weight of rubber components. LIMS enables automation, flashless, runnerless and molding time reduction.

| Injection | When heating | ||

|---|---|---|---|

| Normal | Clamping pressure: low | Evacuating | |

|

|

|

|

| Finished product | Middle density |

Low density |

Low density |

| Grade | Low density and High strength | Super low density | |||

|---|---|---|---|---|---|

Parameter  Product name Product name |

X-34-4347-A/B | X-34-4352-A/B | |||

Appearance |

Reddish brown | Reddish brown | |||

Viscosity 0.9s-1 Pa·s |

A: 223 / B: 226 | A: 248 / B: 265 | |||

Curing speed at 130°C (MDR) s |

T10 | 34 | 32 | ||

| T90 | 65 | 55 | |||

Standard molding condition |

Primary cure | 140°C×35 s | 140°C×35 s | 140°C×30 s | 140°C×30 s |

| Post cure | No need | 150°C×1 h | No need | 150°C×1 h | |

Hardness Durometer A |

38 | 40 | 34 | 38 | |

Density g/cm3 |

0.90 | 0.94 | 0.47 | 0.63 | |

Linear shrinkage % |

2.0 | 3.0 | -7.0* | 4.0 | |

Tensile strength MPa |

5.5 | 5.4 | 1.6 | 2.2 | |

Elongation at break % |

600 | 560 | 500 | 630 | |

Tear strength Crescent kN/m |

9 | 9 | 6 | 6 | |

Compression set 150°C × 22 h % |

20 | 15 | - | - | |

* 7% swelling